Infrastructure Solutions

Case Studies & Technical Details

Infrastructure Solutions

Case Studies & Technical Details

Engineered Infrastructure Admixture Technology

Our Technology

Fiber-reinforced concrete (FRC) exhibits better performance not only under static and quasi-statically applied loads but also under fatigue and impact resistance.

Engineered Fiber

AtlantisFiber™, in a strategic partnership with SIERA Group, has engineered an extracted blend of cleaned and refined fibers sourced from repurposed tire fiber strands. From these strands, AtlantisFiber offers two sustainable Repurposed Tire Fiber (RTF) blends that offer many benefits when used in new-build and repair scenarios.

Raw Fiber

An extensive amount of R & D was done using raw fiber in its original form.

Processed Fiber

The advantage of the processed fiber is that it allows for better performance due to higher dosage rates and improved mixing characteristics.

AtlantisFiber's EnviroGuard–100 Polymeric Fiber Concrete Admixture was used in the following projects, demonstrating the efficacy of RTF (Repurposed Tire Fiber) in both slab and thin-set mortar repair covering several years of exposure/data.

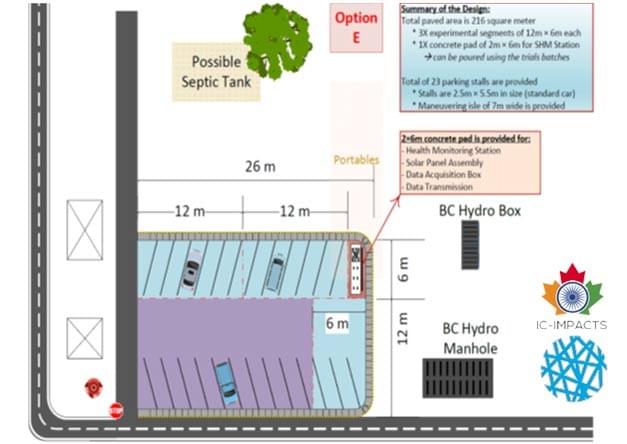

Chawathil Field Demonstration

Pavement Project

Technical Set-Up & Results

This project was measured by sensors that were embedded in the concrete. Pump-trucks and mixing characterizations were also analyzed.

Our Sensors

Embedded strain/temp & humidity sensor.

Control Box

Solar powered control/data acquisition box

Junction Box

Electrical junction for the control/data acquisition box

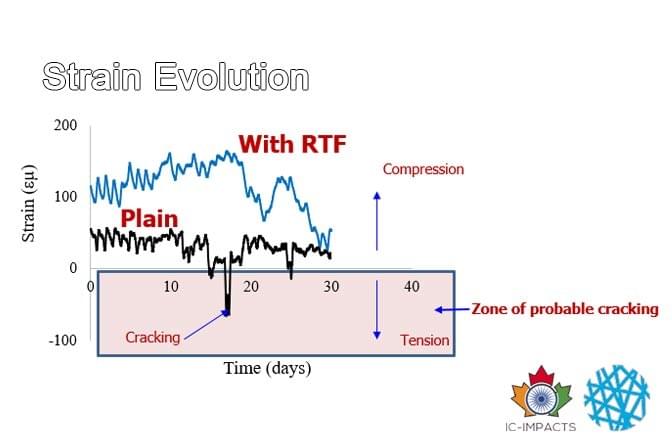

Strain Evolution

Tension stresses cause cracking (see the appreciable improvement of RTF vs Plain)

Post-Pour Loading

Finished project.

In order to monitor the performance of the pavement, the team embedded 30 solar-powered sensors that transmit data to IC-IMPACTS researchers. These health-monitoring sensors provide 24/7 data that will enable efficient future designs and improvements in the self-healing pavement technology.

Slab Preparation

Slab preparation for concrete boom pump and parking lot pour.

Aerial View

Birds-eye view of post pour - control vs fiber reinforced.

Project Site

Completed within the Chawathil First Nation community in BC, Canada

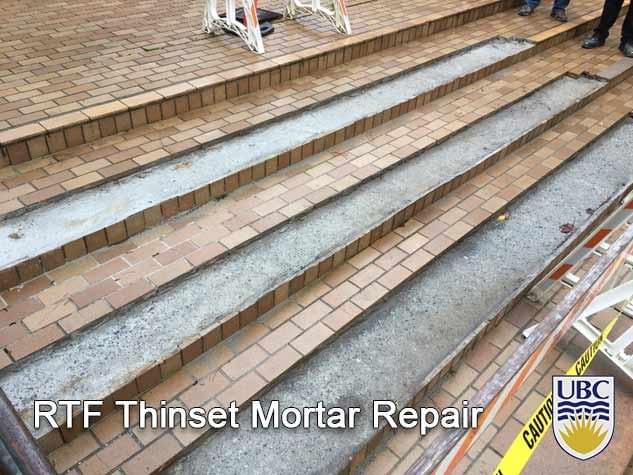

H. R. MacMillan Building Project

This UBC project was for the courtyard steps analyzing thinset mortar repair. These "thin set mortar projects" capture the best scenario for the likelihood of cracking, allowing the opportunity to effectively measure the varying mix effectivenesses.

UBC Campus

The University of British Columbia is a public research university with campuses near Vancouver and in Kelowna, British Columbia. Established in 1908, it is British Columbia's oldest university. The university ranks among the top three universities in Canada.

Courtyard Steps

- Construction Type: Concrete and brick

Thinset Mortar Repair

Our RTF admixture largely mitigates the high concentration of cracking normally associated with high-cementitious mortar repair work.

Data Acquisition Box

Data points collected every 5 minutes.

Data Acquisition Box

Inside the box

Sensor Placement

Strain Gauge Sensors

Batch Mixing

Lab Technician at UBC mixing a batch of RTF.

Troweling The Steps

Note the smooth finish despite the high-fiber dosage.

Curing Steps

Thinset mortar repair was done on this high-traffic set of steps.

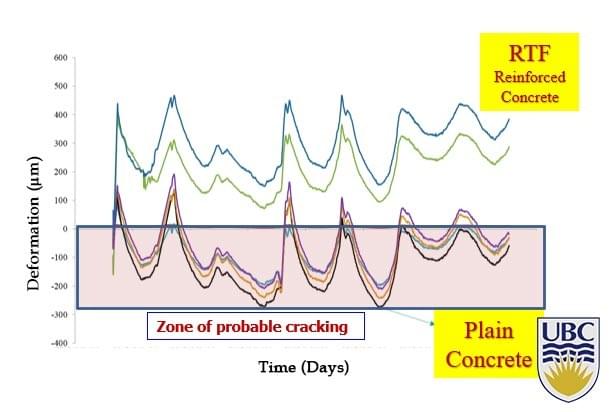

Mix Descriptions

Control (plain concrete) vs four varied RTF dosage rate mixes.

Strain Results

Significant average improvement of RTF mixes vs plain

All Content and Images © 2024 All Rights Reserved | Atlantis Holdings, Ltd

AtlantisFiber recognizes a long & strong strategic partnership with Dr. Nemkumar Banthia, SIERA Group and IC-IMPACTS

Proudly built by Cortex Marketing | Problems with this site? Contact the Webmaster.